Projects

Cistern for Rain Water

Structural Roofing and Waterproofing

Client

Yorkdale Shopping Center

Location

Toronto, Ontario, Canada

Project Type

Structural Roofing and Waterproofing

Cistern for Rain Water

Structural Roofing and Waterproofing

Problem

Yorkdale Shopping Centre is a major retail shopping mall in North York, Toronto, Ontario with 18 million annual visitors. In 2016, London, ON-based construction manager Ellis Don undertook Yorkdale’s 300,000 square-foot, $331 million expansion, bringing its total size to 2 million square feet. The expansion consisted partially of a news level below grade parking structure, which experienced water infiltration issues through the foundation walls of the customer parking spaces, ventilation shafts and mechanical rooms. The foundation walls that were leaking in levels from P2 to P5, was caused by a gray cistern which was constructed during the renovations. Grey-water or sullage is all waste water generated in households or office buildings from streams without fecal contamination, i.e. all streams except for the wastewater from toilets. Sources of grey-water include, sinks, showers, baths, clothes washing machines or dish washers. As grey-water contains fewer pathogens than domestic wastewater, it is generally safer to handle and easier to treat and reuse onsite for toilet flushing, landscape or crop irrigation, and other non-potable uses.

Solution

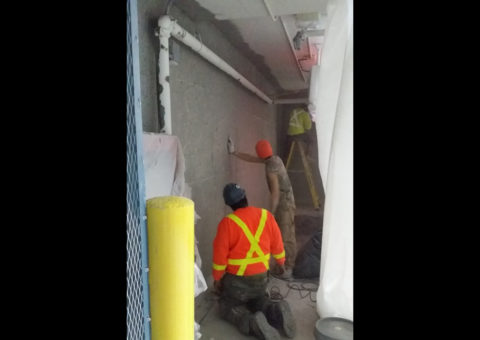

Kelso Coatings was engaged by Structural Roofing and Waterproofing Ltd. to mitigate the leaking issues. Kelso employees trained and certified Structural Waterproofing on the installation of the CN 2000 waterproofing system for this project. Often used in concrete structures like parking garages, the CN 2000 system provides a seamless membrane that will not tear, puncture, or wear over time. As a matter of fact, the CN2000 waterproofing system performs better over time. It was successful in stopping all leaks at the Yorkdale garage, making this structure permanently dry. The client saved an enormous amount of time, inconvenience and money by applying the CN2000 system to the opposite side (negative side) of the water and was successful to resist the extremely high water table and hydrostatic pressure.

Process & Highlights

- All walls sand blasted and cold joints/ cracks chased

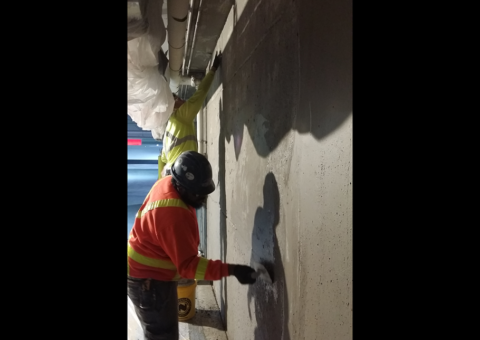

- Structural Waterproofing who is a certified application crew applied two coats of CN2000B on the foundation walls.

- Finally the walls were painted with a breathable paint.

- Significant cost savings to the client as well as time.

Products Used

- Structural did an outstanding job on the application of the CN2000 waterproofing system.

- After sand blasting all walls on the various levels of the parking structure, Structural identified all active leaks and with the use of CN2000A, terminated all visible signs of running water.

- CN2000B was then mixed in specific ratio with water for a brush application of CN2000B.

- After initial set, of the first CN2000B coating, a second batch was mixed to be applied in a perpendicular direction of the first coat using a trowel.

- To save time and money, 1 coat of CN2000C&D was applied on the surface of the CN2000B coating for curing purposes. This will keep the CN2000B crystalline material hydrated, allowing the active materials to penetrate the concrete.