Projects

Oshawa Mall

Repairing & Waterproofing a Fire Exit at Oshawa Mall

Oshawa Mall

Repairing & Waterproofing a Fire Exit at Oshawa Mall

Problem

Built in 1956 as an open-air shopping centre, Oshawa Centre (OC) has been an integral part of the Durham Region for nearly 60 years. OC stands alone as the largest super-regional shopping centre in the eastern portion of the GTA at 1.2 m ft2 (111,500 m2). With over 250 retailers, OC creates a unique shopping experience with sought-after brands. Following a $230 million investment, OC has added 260,000 ft2 (24,155 m2) of retail space, up to 60 new stores, a 1,000-seat food court and 2 new restaurants. Oshawa Centre was one of the first to be recognized for excellence in environmental management and performance, achieving BOMA BEST Level 4 certification. The centre will continue its exceptional leadership in sustainability and environmental practices.

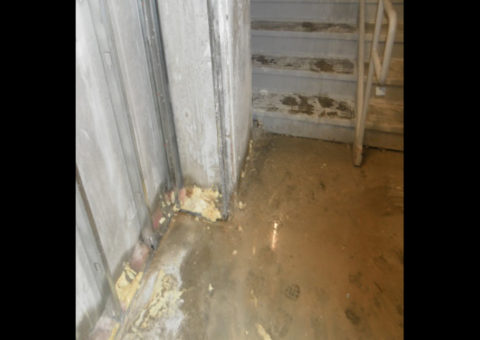

The challenge was that the crystalline coating that was previously specified and applied on the foundation walls in the newly built fire exit had failed. Additionally, the injection method was unable to terminate the leaks occurring. The grand opening was approaching and the owner’s were not able to open until the fire exit was 100% dry.

Solution

HCM, who is one of Kelso’s certified application crews, along with Kelso, mobilized immediately to remove the previous failed crystalline coating and all injection ports to prepare the surface for the CN2000 waterproofing system. The crew worked around the clock on minimal notice and were successful to terminate all the active leaks and waterproof the entire fire exit (walls and slab) using the CN2000 waterproofing system. The client was impressed with the performance of CN2000 as well as meeting the deadline and budget.

Process & Highlights

- Remove all dry wall and steel studs to expose the foundation walls.

- Bush tool all areas to remove previously installed crystalline coating and scarify the surface.

- Remove all previously installed injection ports.

- Cut a section of stair well out to have access behind the stairs.

- After terminate all the active leaks with CN200A, HCM applied 2 coats of CN2000B on the interior surface of all foundation walls and kept the CN2000B coating hydrated with

- CN2000C/D, which is a cementitious polymer membrane.

Products Used

- The CN2000 waterproofing system was applied on this structure.

- This consists of CN2000A for active leaks, CN2000B crystalline waterproofing, which becomes an integral part of the concrete, with self healing capabilities and topped off with CN2000C/D for curing.