Projects

Pedestrian Tunnel Under Lake Ontario

Construction of a watertight tunnel

Client

Toronto Port Authority

Location

Toronto, Ontario, Canada

Project Type

Construction & Waterproofing

Pedestrian Tunnel Under Lake Ontario

Construction of a watertight tunnel

Problem

This pedestrian tunnel, located 40 metres under Lake Ontario, was recently awarded the Canadian Project of the Year Award for 2014 from the Tunnelling Association of Canada. The tunnel will improve access to Toronto’s downtown airport, which is currently only accessible by ferry, and will accommodate the movement of more than 1,000 people per hour.

Arup is the lead engineering designer for the project, responsible for the design of the tunnel and the associated water and sewer mains. They are also providing structural, mechanical, electrical, plumbing, geotechnical, civil, utilities, acoustic, IT, communications, fire/life safety code, and security consulting.

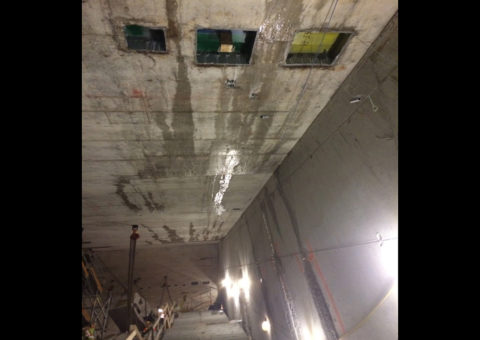

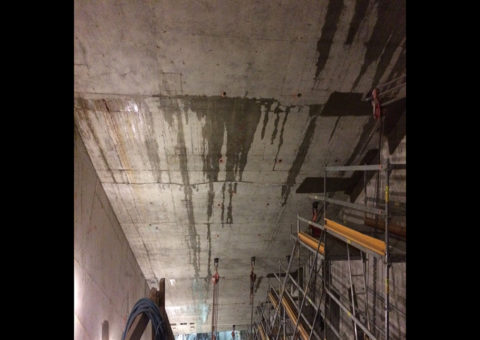

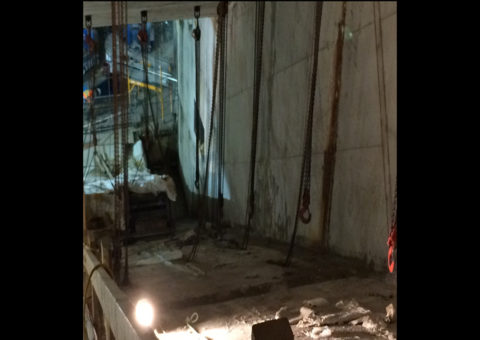

There was an issue of localized water infiltration in the shafts and tunnels. This prevented the finishes on the walls, ceilings, elevator pits, mechanical rooms, etc…to be completed. HC Matcon, who is one of Kelso’s certified applicators, along with Kelso management, set up a plan of attack to terminate all leaks in short order since the tunnel had to open for the Pan Am Games by mid summer.

Solution

The Canadian Association Project Awards recognize deserving individuals and projects in the Canadian and worldwide tunnelling sectors. This project was selected for the project team’s ability to not only work within a constrained site while keeping the airport fully operational, but also for overcoming the engineering challenges involved in the construction of a watertight 10-metre-wide tunnel, 40 metres below the lake.

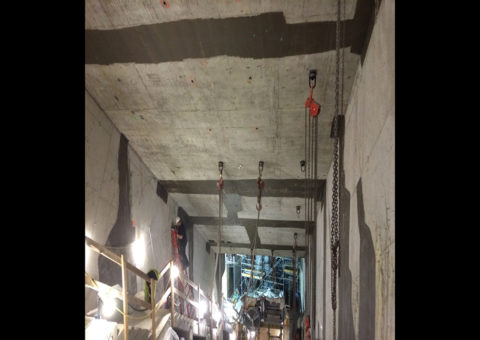

With the assistance of the PCL, the escalators were removed and some areas of the stairs in order to give us access to prepare and apply our CN2000 crystalline waterproofing system. The CN2000 system has been tested by Queen’s University at 3.3mpa to determine the hydrostatic pressure CN2000 is capable of resisting when the CN2000 system is applied on the negative side of a concrete structure. The results were that the CN2000 crystalline waterproofing system is capable to resist the hydrostatic pressure 22 times more than the uncoated sample at 3.3mpa. This project illustrated the extreme hydrostatic pressure our CN2000 system is capable to resist when applied according to technical specifications. The tunnel was completed and opened on time for the Pan Am Games in Toronto.

Process & Highlights

- PCL to give access to HCM in the various locations where there was visible water infiltration. This included accommodating HCM with scaffolding, lighting, heating, etc…

- PCL recognized for the health and safety record, provide HCM all equipment and monitoring required to continue their immaculate record and reputation.

- HCM worked 2 shifts and weekends to meet deadline.

- The water infiltration assisted HCM with the application, since the CN2000 waterproofing system must be applied on a wet surface.

Products Used

- Most critical part of project was to terminate the active leaks with running water. This was accomplished using the CN2000A insta plug material.

- Once all leaks were arrested, the certified applicator applied two coats of the CN2000B crystalline waterproofing on the areas identified by the GC and engineers. Depending on the amount of water infiltrating, determined how many inches we would coat on both sides of the crack or seepage area.

- After the second coat of CN2000B has initially set, HCM applied one coat of CN2000C&D on top of the CN2000B coating. This allows our CN2000B crystalline coating to remain hydrated and allows our activating materials to migrate into the substrate, which in turn will trigger a chemical reaction producing insoluble crystals. This in turn will fill the naturally existing pores and micro-cracks in the concrete but will still allowing the concrete to breath.